Xeikon Café made the virtual transition this year, with the company debuting Xeikon Café TV, an online event held April 22-23 that connected printers and brand owners to learn about the latest in digital printing technology and applications.

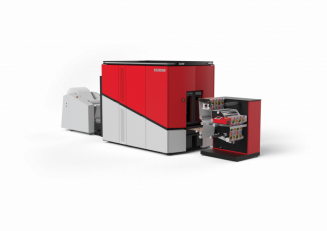

The Xeikon CX300 dry toner label press.

The livestreamed presentation featured insights from a variety of industry experts, covering the rise of digital production technology in labels and packaging. Additionally, Xeikon executives provided overviews of the company’s latest technology.

Mark Hanley, president of I.T. Strategies, a research and consulting firm with a focus on digital printing, shared projections for the future of digital printing. While conventional output is higher than digital in the label space, he said to expect a significant uptick in digital production as it continues to gain adoption. This is largely due to the value that digital printing brings to the table for printers and their customers.

“This value positioning contributes elevated profit at lower volumes for label converters,” he said. “[Digitally-printed labels] also enable new market and customer development in a way that analog technology has not done so much.”

While digital appears poised for significant growth in the label segment, with several technologies and options on the market, it’s imperative that label and package printers seeking a digital solution find the right fit for their specific needs. Filip Weymans, Xeikon’s VP of worldwide marketing, explained that finding that right fit can mean analyzing needs in manufacturing processes, business verticals, embellishments and converting, workflow, software solutions, and more.

Weymans then provided an overview of Xeikon’s latest digital press for the label segment, the Xeikon CX300. The press features Cheetah 2.0 dry toner technology and is designed for overall equipment effectiveness, with speeds reaching 98 fpm.

Jan Vercammen, product manager at Xeikon, went into further detail about the new technology, including improvements in press operation, color consistency and stability, and variable data printing capabilities. The five-color press can handle a variety of substrates and can print at 1,200 dpi. The man-machine interface (MMI) software also allows for remote information access and intervention on the press.

To provide the printer’s perspective on the latest in digital technology, Nikkie Freeman, chief commercial officer for Stouse, Inc., shared her company’s experience with digital printing and Xeikon technology. Stouse, a New Century, Kan.-based producer of a variety of print products, initially focused on screen printing, Freeman said. But with an increased demand for faster turnaround times, shorter runs, and lower inventories, along with growing advancements in digital technology, the company made the decision to invest in digital printing.

“We added our first digital press, which was a sheetfed press, in 2003, and we have gradually increased our digital capacity ever since,” Freeman said.

In January, Stouse added its latest digital press, bringing a Xeikon 3500 digital press on board for folding carton production. With the company’s digital output beginning to exceed its conventional, Freeman praised the user-friendly attributes of the Xeikon 3500.

“The machine is fairly intuitive to run for someone who is tech savvy,” she said.

While Stouse has experienced a successful digital transformation, the process of digitization can be challenging for packaging and label printers, and requires more than just a cursory assessment of the technology. Pat McGrew, an industry consultant and managing director of McGrewGroup, shared how the process of a digital transformation often requires multiple steps and iterations.

“Transformation is like shampooing your hair,” McGrew said. “It’s lather, rinse, repeat. It’s iterative, and it’s not going to be one silver bullet that is going to get you through transformation.”

She explained that in many instances where transformational initiatives fail, it’s because key milestones are missed, objectives are not met, and the initiatives end up getting shut down before they are fully realized.

McGrew detailed how effective strategies for transformational change often require executive support, clear product management, and positioning the company for digital growth. But most importantly, communication to staff members is key to success in digitization efforts.

“A lot of organizations I've done assessments for only communicate to the staff things they think they need to know,” McGrew said. “But in order to accomplish transformational change, to get ready for the new realities we're all going to be facing, you're going to need everyone to be on board.”

Converter Cuts Turnaround Times, Manufacturing Costs

Converter Cuts Turnaround Times, Manufacturing Costs

HP Announces Forthcoming Leadership Transition

HP Announces Forthcoming Leadership Transition

Packaging Impressions Parlor: Addressing Efficiency Among Converters and Brand Owners

Packaging Impressions Parlor: Addressing Efficiency Among Converters and Brand Owners

The 2025 PRINTING United Alliance Pinnacle Product Awards Program Now Open for Entries

The 2025 PRINTING United Alliance Pinnacle Product Awards Program Now Open for Entries

2025 Packaging Outlook: An Opportunity for Growth

2025 Packaging Outlook: An Opportunity for Growth

Adoption Trends for Digital Printed Packaging

Adoption Trends for Digital Printed Packaging