A Refreshing Transition

When Nestlé Waters North America (NWNA) approached prepress and consulting firm CSW, Inc. with a mission to transition its package printing to expanded gamut color, CSW braced itself for a long process – one that could take months, if not years. But when Nestlé requested all of its packaging be converted to expanded gamut and be an exact match to what it already had on shelf, CSW had to switch into high gear.

The change, explains Andy Schopps, director of packaging operations at NWNA, came as a corporate mandate because expanded gamut would provide the company the ability to gang runs that had previously been separated.

CSW worked tirelessly to get its internal prepress team, outside designers and printers ready to make the transition as seamless as possible, all while keeping the new printed packaging consistent with the legacy products. Brand color fidelity is crucial and any change in appearance may bring to mind doubts about the quality or freshness of the product.

“The worst thing you can do is give the end user the feeling that something looks different,” Marek Skrzynski, director of graphics at CSW explains. “The question of ‘is it fresh?’ comes up.”

Renée Walsh, vice president of sales and marketing at CSW adds, “When consumers have those questions in mind, it could impact purchasing decisions.”

Cohesion Among Partners

CSW works with brand owners, designers and printers to bring a concept to reality. When brand owners have something they have decided to commercialize, they turn to CSW, normally with an outside design firm and printer in mind.

“It’s a highly collaborative process,” Walsh says. “We’re the handshake between the two.”

So when NWNA came to CSW with the mission to transition all new package printing to expanded gamut, CSW knew that it would have to help NWNA get all of the designers and printers on board with the idea, in a seamless collaboration.

In the beginning stages of the project, CSW presented the benefits of expanded gamut to each partner involved. Skrzynski explains that the team presented the effort behind the project as “one standard ink set to effectively simulate a vast number of spot colors. By doing so, [they would] reduce the brand’s packaging costs with an improved or at least uncompromised visual impact.”

CSW explained to the design team that it would no longer be limited to pigments of spot colors, allowing for more photorealistic printing. Expanded gamut would give the designers the ability to create more complex color blending and cleaner transitions of the colors.

“You can have healthier, more natural flesh tones because we are no longer limited to the yellow/magenta separation,” Skrzynski says.

Not only did CSW paint a picture of opportunity for the design team, it offered a numerical outline with hard numbers. It estimated that if using a four-color process, the designers would have access to approximately 45 percent of the Pantone library.

However, depending on the substrate, expanded gamut would open up approximately 80 to 90 percent of Pantone colors, almost doubling the color availability.

“Cost savings aren’t really relevant from a design standpoint,” Jill Tapia, director of production strategy and planning at Cornerstone Strategic Branding, the design firm that worked with CSW on the NWNA project, explains. “We were normally limited to eight colors in our projects with Nestlé. This opened up opportunities for us. CSW pushed the boundaries of what could be done with expanded gamut.”

Cornerstone prides itself on having an understanding of both the design elements and the “technical limitations” of packaging, Tapia says. The company invested in an Epson 7900 printer, which was first purchased in 2011 and upgraded in 2014, and GMG software to help generate (simulated) spot color targets, so everyone was on the same page. The goal for Cornerstone was to make sure that all of the brands remained consistent.

“For Nestlé we have a large volume of shrink film overwraps and bottle labels printed offset, as well as flexo rollfed, so we strive to keep things cohesive,” she says. “We strive to have no element of packaging less ‘premium.’”

As for the printers, “The project was brought to us by Nestlé,” Pat Kennedy, vice president of The Kennedy Group, one of several package printing companies that works with NWNA, explains. “They introduced us to CSW to bring expanded gamut into our facility … we relied heavily on CSW.”

Mark Buchanan, plate production manager at CSW, sets up the digital plate system to run expanded gamut plates.

For The Kennedy Group, the transition to expanded gamut was quick due to its high-end flexo presses with servo technology. To maintain the highest level of registration, the equipment is automated to make adjustments when necessary. Not only did The Kennedy Group’s client want to transition to expanded gamut, but Kennedy explains that he believed his team would benefit from expanded gamut on an internal level, by creating improvements and efficiencies.

CSW explained to the printers who work with NWNA across the country that because of the influx of shorter runs and SKU proliferation, they would benefit from being able to run multiple short runs at one time. By not being limited to 10 colors, they would be able to run multiple SKUs at once, with different graphics.

Expanded gamut would pave the way for faster setup, quicker makeready and changeover times, reduced ink inventory and would eliminate washup times because the ink would stay the same. Another advantage would be consistency. They would now be relying on predefined ink sets, and with process inks, the definition of a color can be precise.

“So now, all involved printers are speaking the same language,” Skrzynski continues. “They operate within the same criteria and parameters.”

Another big selling point for printers? Reducing pinholes in flexo.

“Unfortunately, flexo is infamous for pinholes in solid areas of a spot color,” Skrzynski says. “In EG printing, all colors are builds, so you never really print with solids. In order to generate a ‘spot color’, you use two, three or sometimes four process inks, so you’re avoiding pinholes.”

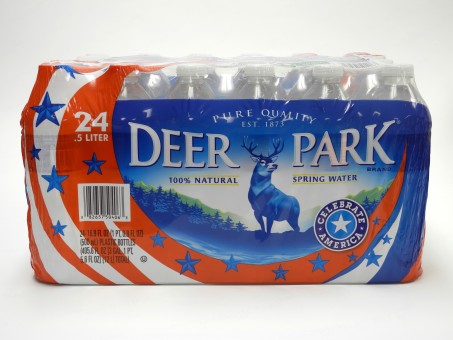

The final step in the process was to convince the brand owners that a transition to expanded gamut would increase overall production, capacity and quality. Skrzynski described it as a mission to demonstrate to the marketing team at NWNA that the conversion would “improve shelf impact with more vibrant-looking packaging.”

Because the project was a NWNA purchasing department initiative, CSW needed to reassure the brand owners that expanded gamut would be the most effective way to transition the brand to more impactful packaging.

“We were helping procurement sell their own program to their own brand managers,” Karen Leet, graphics and marketing communications manager at CSW, remarks.

The team at CSW presented a number of factors that would help educate NWNA on the benefits of expanded gamut printing. The new printing technique would improve visual identity and sophistication of the brand look; it would increase sustainability via the overall standardization of the process; and there would be a reduced time to market. EG would also open up the possibility for more customizable products, including regional, seasonal or personalized promotions. For both printers and brand owners alike, the ability to print shorter, ganged runs without changing the ink has a substantial impact on productivity.

At this point, NWNA decided it wanted all of its existing packaging to be converted to expanded gamut printing, but it had to look exactly like the existing packages on shelf.

Now CSW was presented with a new challenge. It wasn’t just going to be working with NWNA on an expanded gamut redesign for the future, it would have to get every partner on board to begin readying the existing packaging for the new technique.

With a wider array of color options available, CSW would have to work with the printers and designers to utilize the new library of colors while matching the new proofs to the old ones.

However, it wasn’t as simple as replicating a formulation of Pantone colors to NWNA’s existing color palette for its brands. NWNA’s existing branding incorporated sophisticated spot colors that would be difficult to match. Over the period of approximately a year and a half, and with the help of its color management team, CSW went to each printer to help ease the transition.

“Cost is important, but quality is huge to Nestlé Waters,” Tapia stresses. “The packaging has to evoke the same level of quality as the product has.”

Therefore, the transition would have to be cohesive between the products being produced via the new expanded gamut color pallet and the products rolled out in future designs.

“CSW worked closely with Nestlé Waters to help transition our design and print partners into expanded gamut printing for both legacy items and new designs,” Schopps says.

A Relationship Built on Trust

No matter the project, CSW expresses that a solid relationship is paramount, with transparency and honesty being necessary building blocks. Leet explains that CSW doesn’t just blindly produce what clients bring to the table. The company gives suggestions and tries to guide clients toward what can be done well.

Leet adds that CSW’s role in the relationship “isn’t to say ‘yes’ or ‘no’ all the time.” The company uses its expertise to recommend enhancements that will push the brand further or to suggest alternatives to an idea that may not be feasible.

And when working with many parties toward one end goal, Skrzynski says that CSW likes to operate on a very simple principle: “Do not create false expectations.”

Besides working with designers and printers to understand what can be done realistically, the key, the team explains, is to form a partnership that is built on trust.

Working on behalf of the printer, CSW strived to nail down a design that would be beneficial to the printer in terms of speed and cost, and worked with the designers to optimize ideas, not compromise them.

Similarly, Tapia explains that she believes there are three-steps to making a product look good on shelf: good art, strong separation and quality printing.

“I don’t think any one of those steps can be achieved without the other,” she says. “Collaborating early is key. Having an open dialogue and access to the parties involved is huge.”

That’s why CSW has made it its mission to bring all members involved in this project, and others, to the same page.

“[We are] bridging the gap between each of the individual spokes that create this big wheel of our industry,” Skrzynski continues.

As for the transition to expanded gamut, “you either join this revolution, or the view will never change,” Skrzynski reasons. “The more brands that engage, the easier it will be for a printer to justify the transition."

Related story: Go With the Flow