Go With the Flow

Oftentimes in printing and packaging, the hardware gets all the glamor. And it’s reasonable that the big, powerful machinery running at high speeds and generating that impeccable final label, carton, box or pouch would draw the most eyes and attention. But without a powerful software solution as the backbone of a package printing operation, the flashy hardware will almost certainly not be running to its full potential.

Whether it helps to stay organized, provides editing capabilities, keeps color consistent or provides creative variable data opportunities, software is an integral component to what drives the industry forward. And with so many options and combinations available, selecting the right solution can provide a major leg up on the competition.

Think Differently

According to Bob Raus, the North American category manager for HP Indigo workflow and partner programs, consumers are thinking differently. And because they’re thinking differently, so should brand owners, designers and package printers.

Through the HP SmartStream family of products, Raus explains that several options are available to converters to help them through every step of the process.

“A lot of the value that we bring to customers is really stepping back and looking at their business and helping them understand what we can do to help them be more efficient, add more value, differentiate and get more jobs and grow,” he says.

One of HP’s software solutions providing some of the most outwardly visible value is HP SmartStream Mosaic. This program generates millions of unique graphical patterns from an existing design or automatically creates a new design. Raus explains that this new take on branding can extend brand reach by providing individualized packaging experiences.

Raus says that Coca-Cola recently implemented HP SmartStream Mosaic for Diet Coke labels, developing fresh, exciting packaging for what was previously a standard, everyday product. In doing so, he says, the packaging provided a way for consumers to connect with the brand on a different and personal level.

“When you see a 19-or 20-year-old taking a selfie with a Diet Coke bottle, you know your brand has connected with that person,” Raus says. “That’s a pretty exciting place to be.”

While a workflow software can provide a new way of thinking in packaging design, it can also provide a new way of thinking internally about the printing process. Nick Benkovich, the director of portfolio product management for EFI, explains that before selecting a software solution for their operation, printers need to understand what their foremost products are that they currently produce, what the company would like to add in the future and what the company may run at the current time, but may not in the future.

By understanding these goals for their output, Benkovich explains that companies can then make better decisions on why they are bringing in new equipment or software. For example, he explains that a company can assess the real reasons behind adding a digital press. Benkovich questions if it is solely because of a decrease in run lengths. Or, is it because it can help sell more to existing customers and attract new customers?

Benkovich explains that thinking this way can then help a company determine what it needs a software solution to accomplish.

“Let’s say you pick up a new pharmaceutical or food services company,” he says. “Then they say for the first three months they’d like to come and check the files ahead of time. They need to verify the files ahead of time before you print any. How do you provide that mechanism to them?”

Controlling Color

Because many brands use a variety of different substrates for their spectrum of packaging, ensuring the color is consistent across these varying surfaces is essential. According to Larry Moore, Esko’s vice president, partner programs, North America, a database driven color management system is integrated throughout the entire Esko workflow.

The software, he explains, is able to profile the behavior of inks, providing higher accuracy in reproducing overprint colors. Moore says that because packaging uses a variety of specialized substrates, this software is useful in its ability to provide consistent colors on widely varying surfaces. He notes that metallic substrates are commonly used in pharmaceuticals and sporting goods, and Esko software can profile for

these surfaces.

For example, Esko’s program called Equinox has the capability of profiling expanded gamut printing inks, including orange, green and violet. Not only is this beneficial from a color perspective, Moore says, but it can be helpful from an organizational standpoint as well.

“The beauty behind expanded gamut is most of the digital presses already have some type of expanded ink set on them,” he explains. “We’re able to fully take advantage of the ink sets available on the digital presses. At the same time, we’re able to help customers go to fixed ink palettes on the conventional production side that make it much easier for them to gang runs and optimize their printing work.”

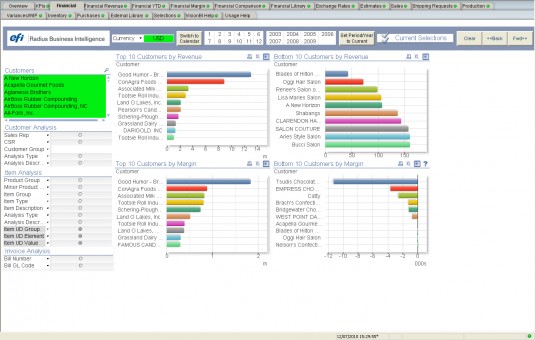

In addition to helping keep color consistent across different substrates, workflow software can also help manage colors across separate devices. For example, Benkovich explains that Fiery XF — a front-end workflow used with wide-format inkjet printers or EFI Jetrion narrow-web inkjet label presses — has color management tools that can recognize the quirks of an individual press and allow it to make the necessary adjustments to keep color consistent.

“You start with the linearization of the device,” Benkovich says. “If a device always has a slightly pink hue to it, when I send the file down, the ICC profile compensates knowing this one’s a little pinkish, this one’s a little bluish, or this one’s a little yellowish in their standard linearization. The profile makes the compensation to make sure you get the consistency of color.”

Where to Streamline, Where to Separate

Adding a workflow software solution can help integrate digital and conventional printing processes, but there are also instances where a software product can help drive just one technology.

In a postpress situation, Benkovich explains, a finishing product cannot determine how an item was printed. Therefore, having a single way to schedule that product to be used can create a simpler process. For example, it doesn’t matter to a guillotine used to cut labels if a job was run flexo, offset or digital. Therefore, creating a single end-to-end process can help a printing operation integrate multiple technologies.

“It’s having a system that provides me a single way for customers to submit jobs, a single way to report those jobs, a single way to connect to those devices, to schedule the work that’s going to happen and ultimately to bill and bill without multiple touch points,” Benkovich says.

While software can provide a tool with which to integrate multiple print processes, Raus says it can also highlight areas where a company may want to focus on just one process.

Moore explains that because each package printing environment is different, it is key to find the right combination of software solutions that are suited for that process. The right combination of software tools, he says, will ensure a seamless process down the line, without introducing any extraneous elements.

“In today’s market, people don’t have the luxury of having one output method,” Moore says. “In what used to be a typical commercial printer, today they may be running some page-based workflow. But they’re also running sheetfed packaging, digital packaging, some sign and display work. So you have to have a workflow that’s robust enough to answer the need of all of the different output devices and do it in a very seamless fashion.”

Because there are limitations in the variability in print that can be achieved using conventional printing processes, Raus explains that HP’s SmartStream products can help companies use digital to fill those gaps. However, this goes beyond just moving short runs to a digital press. He says the key is to think how a brand could be differentiated through digital and to use the available technology to make it happen.

“The value of digital printing is to drive increased business results by connecting with people like never before,” Raus says. “You can easily and profitably create new products that test response rates through micro-marketing by geographic region or special events, and even customize products to speak to each customer differently. This cannot be accomplished with conventional printing. Digital is great for short runs, and while you can buy a digital press to print smaller quantities in your normal operation ... the real value is to think differently ... to almost start a new business division with new thinkers — people that are looking at production in a different way and exploring what can be done instead of what can’t be done.”

Related story: A Refreshing Transition

Cory Francer is an Analyst with NAPCO Research, where he leads the team’s coverage of the dynamic and growing packaging market. Cory also is the former editor-in-chief of Packaging Impressions and is still an active contributor to its print magazines, blogs, and events. With a decade of experience as a professional journalist and editor, Cory brings an eye for storytelling to his packaging research, providing compelling insight into the industry's most pressing business issues. He is an active participant in many of the industry's associations and has played an essential role in the development of the annual Digital Packaging Summit. Cory can be reached at cfrancer@napco.com