Built for Speed

One customer places 330 orders each month, totaling more than one million labels a year. But because that company no longer maintains an inventory of finished labels, each of those orders comes with a two-day delivery window.

“With digital capability, our finished goods inventory has dropped by half,” explains Bob McJury, partner and vice president of sales at TLF Graphics in Rochester, NY. “We have a retail signage client with whom we use an e-commerce front end. So the orders come in, are printed, and shipped in 72 hours. There is nothing on the shelf.”

Another customer—a mid-size retail chain—has color-critical needs, wants to stop franchisees’ habit of buying print locally, and would like to customize many materials for its stores, from labels to POP signage.

“Our world revolves around turning inquiries into cash as fast as possible,” says McJury. To that end, the company produces a variety of product decoration, overlay panels for industrial equipment, and high durability labels and decals for products ranging from small hand tools to giant cranes. Meanwhile, other machines produce eye-catching signage for in-store graphics, exterior signage, banners, floor and wall coverings, and more. And closing the loop, TLF manages it all for customers with inventory controls, warehousing and distribution services.

Partners in Speed. The Head Printologists at TLF Graphics: From left, Bob McJury, Dan Wagner, and Ron LeBlanc.

Equipment and heroes

To deliver on these and similar needs, TLF Graphics draws on a rich mix of digital and conventional printing technology. The fleet includes flatbed inkjet printers, electrophotographic label printers, five screen-print presses, six flexographic presses, computer controlled cutting tables, and most recently, a Durst Tau 330 LFS, an inkjet label press with an integrated laser cutter. An additional 32 pieces of finishing equipment round out the equipment mix.

“Labels are an important part of our business and digital technology lets us work much faster and more efficiently than we could with flexo alone,” says McJury. “We are built for speed and we have heroes inside our company that make things happen and deliver for our customers.”

Many small jobs

All this work amounts to approximately $21 million in revenue split evenly between direct sales and distribution. And when you peel back the layers you find nearly 33,000 transactions a year with an average order size of less than $800, which is a big reason why digital printing technology has become a mainstay of the 35-year-old company.

“We use each machine for what it does well,’ says McJury. “We work based on ‘customer-need-by’ dates and run jobs on whichever press has the availability. For labels, that could be a flexo press, a toner-based digital machine, or the Tau 330.”

The flexo presses remain the workhorses for long run jobs, and are still used for jobs with few or no plate changes. Yet as customers increasingly seek shorter runs, look to minimize inventory levels, have multiple SKUs, and expect very short turnaround times McJury says digital presses, especially the Tau 330, have transformed the nature of his business. Many digital presses can do high quality work, he notes, but because they lack speed compared to flexo presses, they are often limited to shorter runs, perhaps up to about 5,000 feet. He has found their speed and throughput fills certain needs, but his customer mix requires more flexibility.

“The Tau prints 14˝ wide and can do runs of half a million labels,” says McJury. “For long runs the flexo presses can run much faster—300 or 400 feet per minute—but those runs are somewhat less common because of the trend to shorter run lengths and the need to accommodate more SKUs. Together, these facts make the practical speed of a flexo press between 80 and 200 feet per minute, while we get about 150 on the Tau, so it’s often more practical to run jobs on the digital press.”

According to McJury, digital printing accounts for some 30 percent of the company’s business, up from just 5 percent just five years ago. This has come from new and existing customers but also from other printers who look to TLF to handle the short-run jobs. And those aren’t just coming from small shops. Knowing about the Tau 330, a large commercial printer recently singled out TLF, because they knew the Tau would be able to deliver a job within a tight print window.

Key factors

“Our primary market is industrial labeling,” says McJury. “We think the lightfastness and durability provided by the Tau is going to help expand the amount of digital work we do. The key to that market is durability, followed closely by image quality and speed, and we can reliably and consistently provide those with this press. The image quality falls between flexo and screen in terms of durability, and the ink laydown is much better than on our other digital presses.”

The speed and productivity of the Tau go beyond its ability to handle some of the shorter runs that come in. It is opening up capacity on the six flexo presses to run longer jobs, including some that TLF might have turned away just a few months ago. “The long flexo runs are still around and there are jobs we can run now—4 to 6 million labels—that we wouldn’t have had the capacity to handle before because of shorter jobs taking up press time,” says McJury.

Invisible ability

This is hardly unique to TLF. Such press optimization is becoming increasingly common in shops that have added digital presses. In many shops, jobs using the same substrate are

ganged onto digital presses where they can run without stopping, even though each job may only be for a small number of labels. Meanwhile, the flexo presses are fired up for the long runs they do best. This is the somewhat invisible ability that a digital press often brings to a converter. While the real-world effectiveness varies from shop to shop, it is further proof that digital and flexo are very much complementary, rather than competitive technologies.

Although McJury admits to having had to adjust to the higher cost of ink for the Tau, both he and his customers appreciate other features, such as not having to make plates or screens, saving on both labor and materials, while the integrated laser cutter has drastically cut the need for dies.

“If we added up the cost of the dies we have stored to meet all the different job needs, they could be worth as much as our building,” jokes McJury. “Having the laser cutter means we don’t need to make as many dies and we expect to see die purchases decrease by as much as 50 percent.” And that kind of savings, for the company and its customers, is not a joke, nor is the process time saved by not having to wait for a die to be made and delivered.

Of course, the laser can’t cut every material and PVC, BOPP and some other go-to materials for many industrial labels don’t react well to the heat of a laser beam. Yet this is not posing a challenge for TLF. A modular ABG International Digicon sits but a few feet away from the Tau, ready to take jobs that need different cutting and finishing options than the Tau can offer.

Quality not an issue

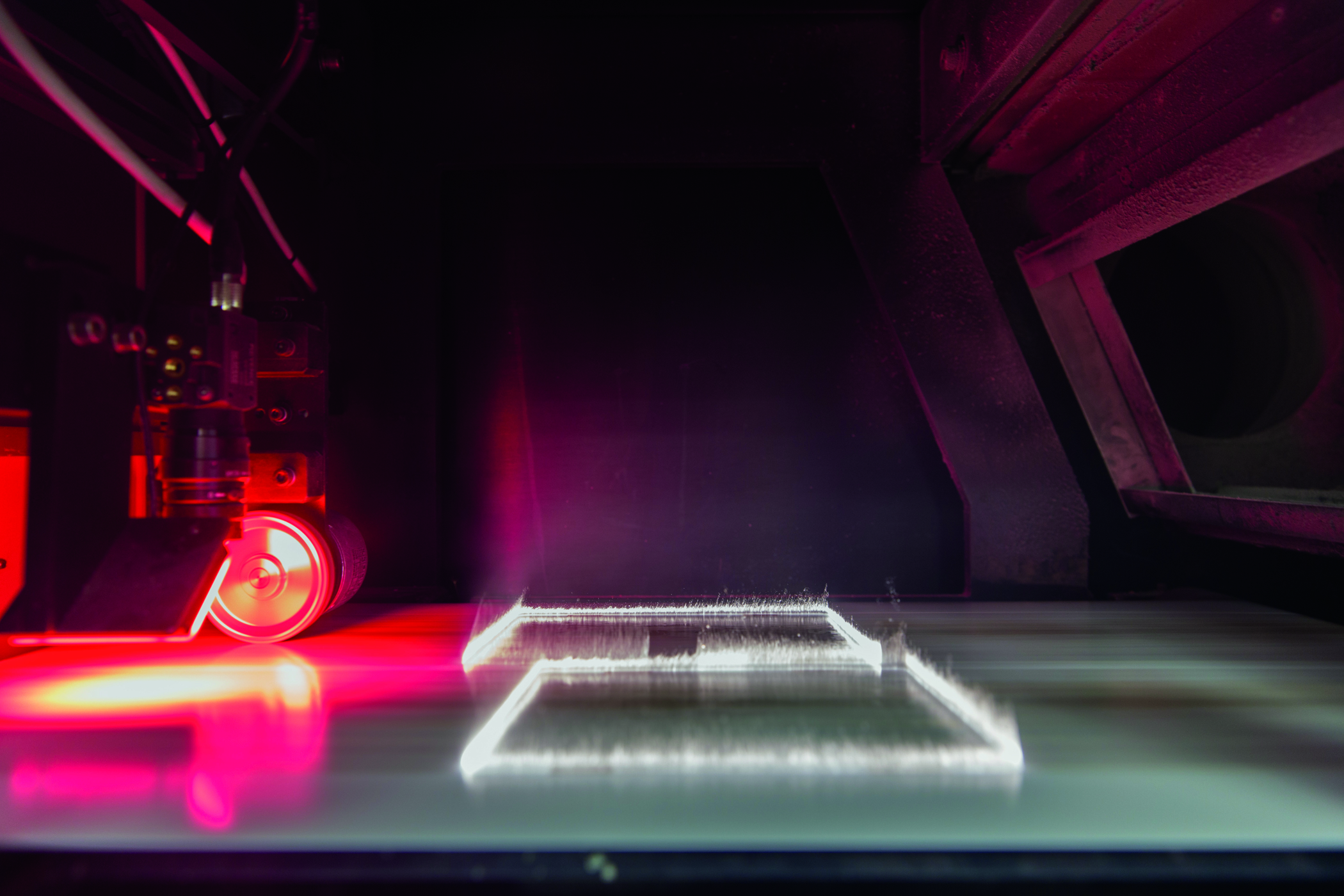

The inline laser cutter on the Tau 330 LFS streamlines label production and sharply reduces the need for mechanical dies.

What is perhaps most telling about TLF Graphics and the state of digital printing in the labels and packaging space is that the discussion of print quality and which press to use rarely comes up. In fact, how a job will be printed is not usually part of customer conversations. Press choice, usually made at and by TLF, may be based on the need for a specific spot color. Some customers may prefer a flexo look and feel, or that of a toner-based press. But in most cases customers just want their labels delivered quickly, cut into the shape they prefer, and with the right level of quality.

“It really all goes back to the heroes I said are working here,” says McJury. “We’re an integrated, collaborative team of engineers, pre-press artists, press-operators, and customer service pros all working together to deliver a truly great product.”